Manufacturing System

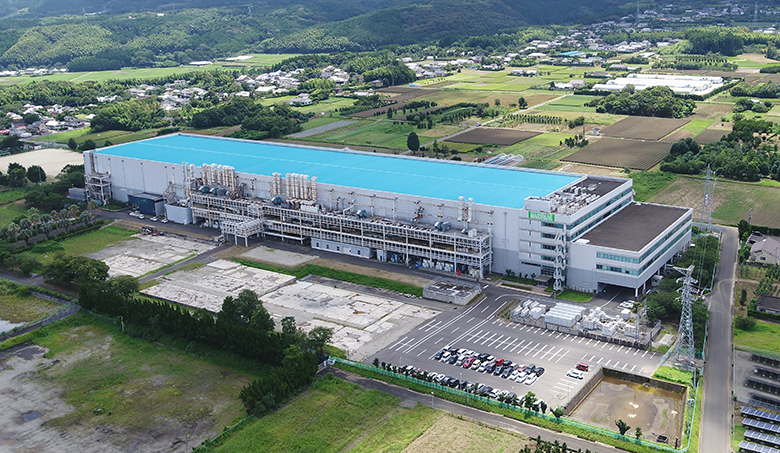

FACILITY

Capital Investment in Advanced Technologies

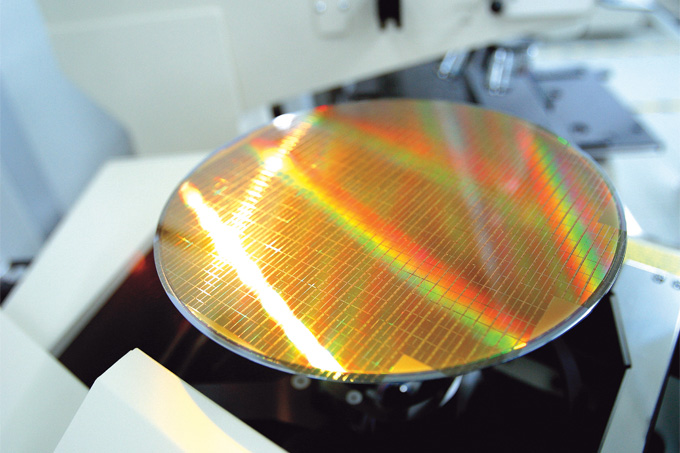

Our Products

Marumae manufactures components that serve as the core units of semiconductor and flat panel display manufacturing equipment.

Major Processes in Which Customers Use Our Products

- Etching

- CVD

- Coater/developers

- Sputtering

- Single wafer cleaning

- Ashing

- Wafer bonding

- Ion implantation

- Annealing

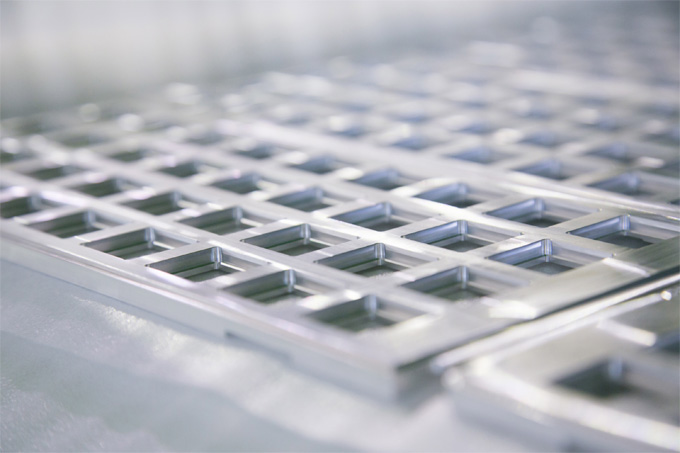

Our Main Products

- Vacuum chambers

- Shower heads

- Exhaust plates

- Electrostatic chucks

- Heaters

- Upper electrodes

- Targets

- Parts for transfer systems

- Other vacuum components

Locations

High-precision components for equipment to manufacture semiconductors

High-precision components for equipment to manufacture semiconductors and flat panel displays

High-precision components for equipment to manufacture semiconductors

Main Facilities

Automated Production Line

Electron Beam Welding (EBW) Equipment

Double-column 5-face Milling Machines

Intelligent Multitasking Machines